Site Analysis Understanding project conditions

Design and Engineering Services

Procedure of Conception, Design, and Engineering

Preliminary Research Evolving clients needs

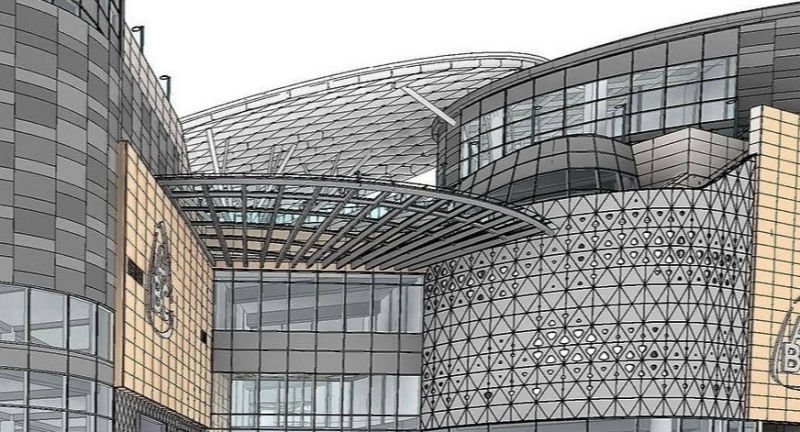

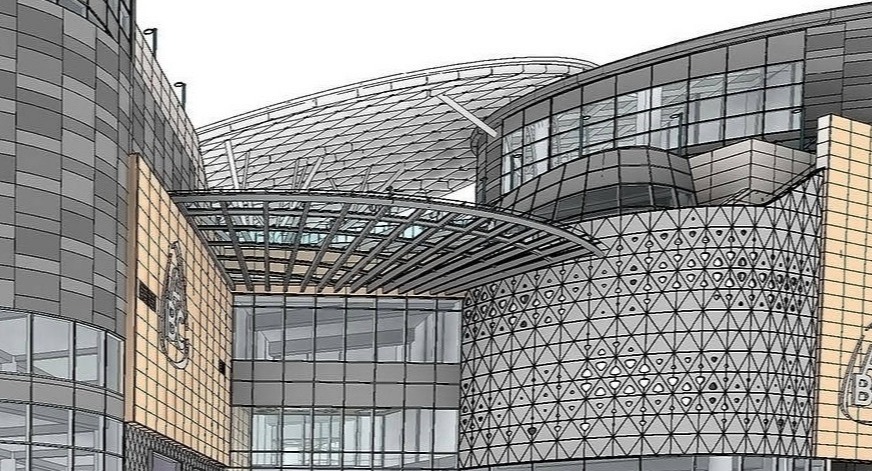

Concept Design The marriage of modern design with practical needs

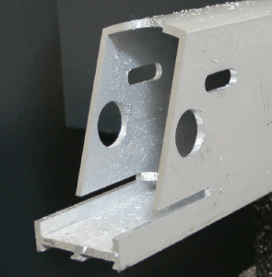

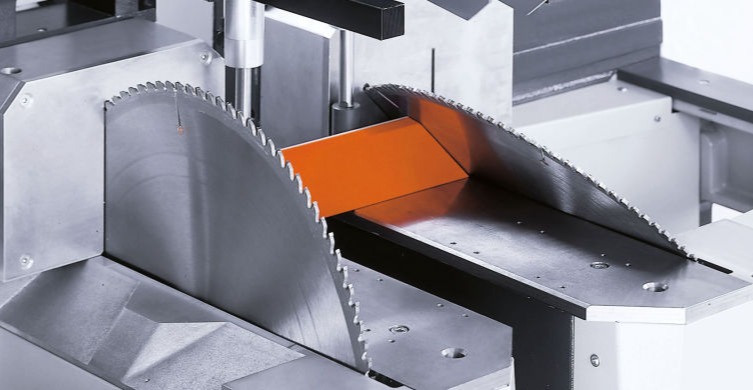

Product Selection Accurately matching products to save money and meet the needs

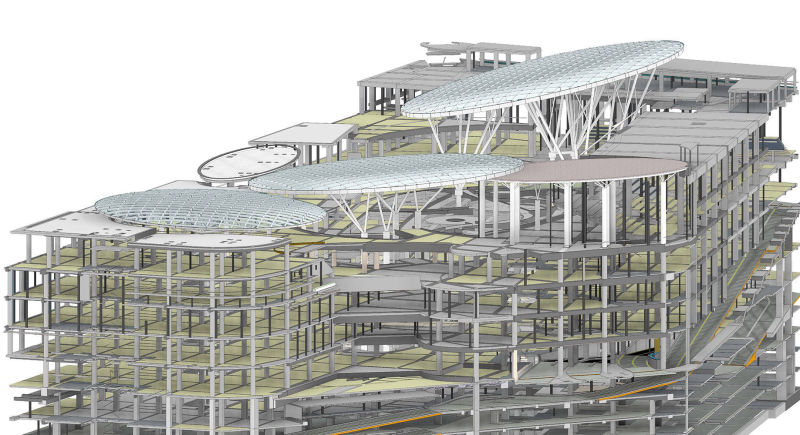

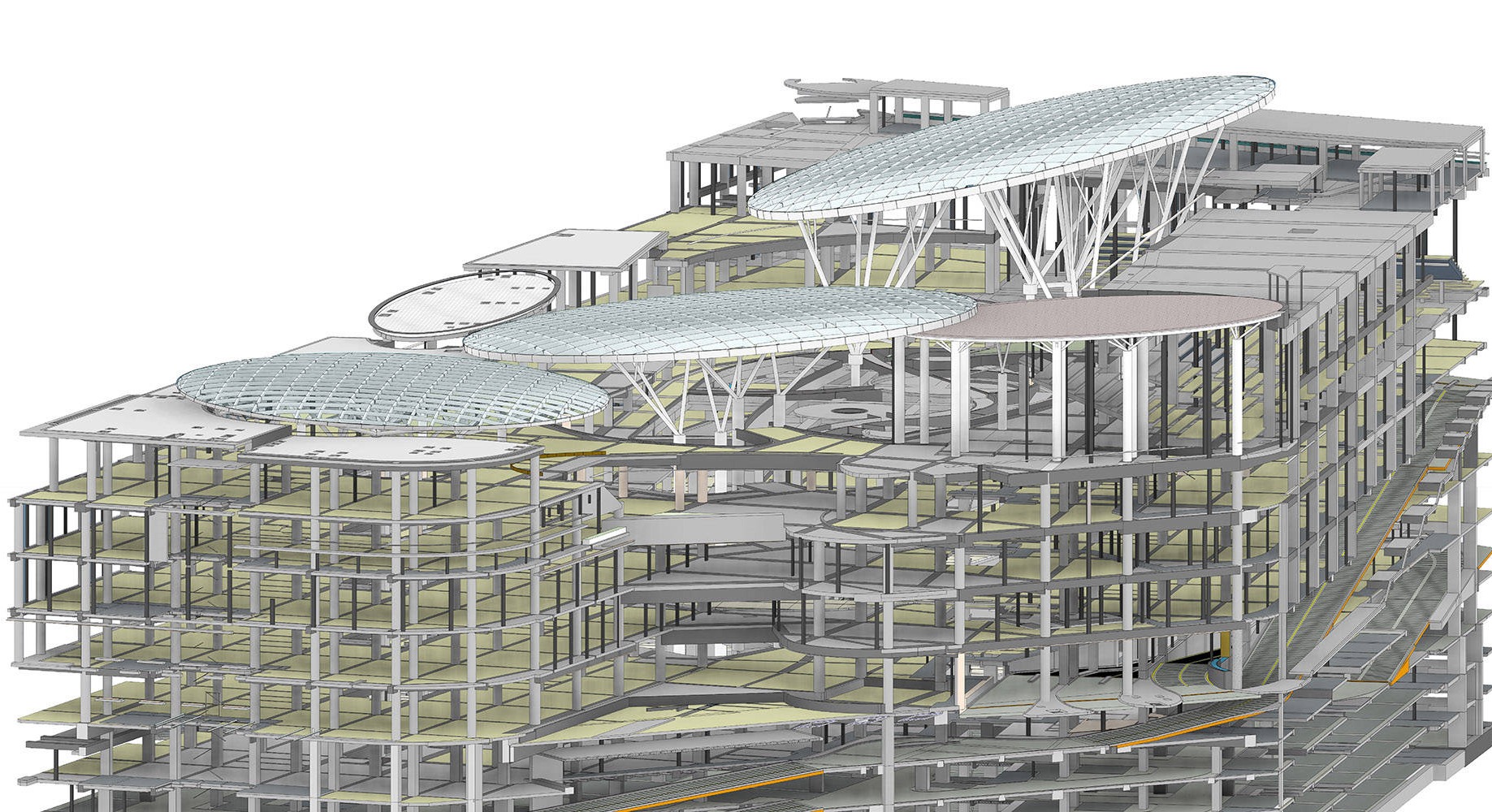

Structural Analysis Simulating structures, to reinforce failing elements.

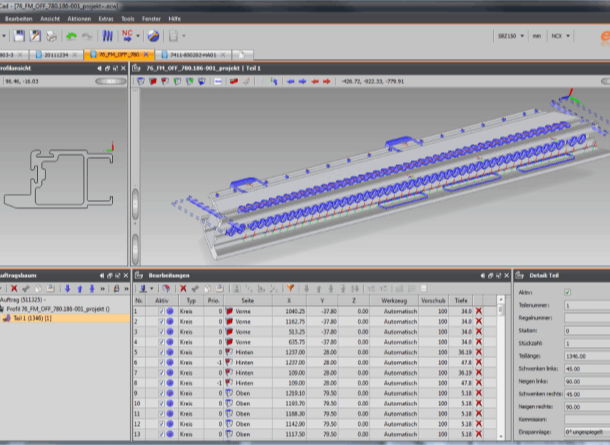

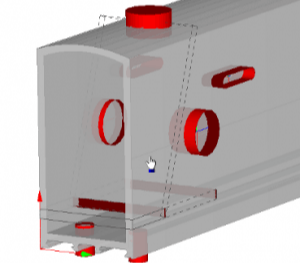

Shop Drawings Drafting detailed section drawings

Design Approval Iterating all of the above until total client satisfaction is achieved.